Date:2023-01-03

Industrial automation in the manufacturing plant helps to improve the speed and accuracy of production. Usually, the most direct way to achieve these goals in the automated shop floor is to reduce the weight and increase the stiffness of the robot, especially the end-effector.

Lightweight end-effectors translate directly into high production speed and accuracy, effectively reducing motor and actuator load and improving reliability. For many industry applications, a 0.1 second reduction in cycle time can mean a savings of $300,000 or more per year. A foreign company saved $1 million a year by providing custom-made carbon fiber robotic arms to partner companies.

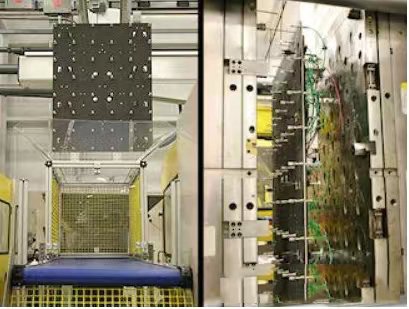

At present, carbon fiber structural parts have been widely used in foreign robotics and automation design. For example, some basic structural materials in automation structure, such as plate, Angle steel, cap reinforcement, C-shaped channel, rectangular tube, and portable end-effector can be easily designed and realized with carbon fiber.

With the use of carbon fiber, the 40 pound end-effector can be reduced to 15 pounds or less. Reduced vibration and bearing and motor wear. By utilizing a professional composite tube connector system, square and rectangular tubes can be connected to flat corner braces, resulting in a very strong and lightweight frame. Extruded round tubes can also be easily connected to form trusses through a system of universal joint connectors.

For carbon fiber customization solutions for automated products, custom components and assemblies in carbon fiber materials are available, such as capsule high-mold carbon fiber prepregs with complex geometry or minimum weight. And combined with the robot operating temperature. Carbon fiber can be used in high temperature operating environments by matching with high temperature resistant resins.